Più di 100 anni di progresso tecnico ci hanno resi leader nei settori degli Inverter, dei servoazionamenti, della tecnologia di controllo e della robotica.

Expanding welding work with robot welding cell

In 1978, Janco de Jong turned his hobby into his work, starting with metalwork such as candlesticks and chimney caps. When the oil crisis came in the 1980s, it brought a lot of demand for wood stoves. At that time, De Jong designed his first wood stove and today the Frisian company exclusively produces the JAcobus wood stove and related items. Including production, the company now employs 20 people and produces about 4,000 stoves per year, with the help of a number of Yaskawa (welding) robots.

More efficient

"Design, prototyping, production, production automation, we do it all ourselves. We outsource laser cutting and certain turning work but the sheet metal work and welding is done by us," explains owner Rudolf de Jong, son of the founder. The main production location is in Poland where the company has its own site. There is a twin welding plant there with 2 Yaskawa robots and a large manipulator. "In Poland we complete the welding of the JAcobus wood stoves. There is also a welding cell for smaller parts but the capacity was too tight, so now they weld one part there and in the Netherlands the other parts are made in the Yaskawa welding cell." The majority of the material for these parts comes from the Netherlands, so it was more logistically efficient to keep the welding operations local.

Good contact

Not only do the welding robots in Poland come from Yaskawa, there is also a press brake with a Yaskawa robot in front of it. When the decision was made to invest in a welding cell, the step to Yaskawa was a logical one. "I called you guys to ask if you could integrate robots in welding cells," says De Jong. "But Yaskawa has ready-made welding cells. That is absolutely ideal, we didn't have to think up anything else. And because it is a standard Yaskawa product, the price is also better. This was by far the easiest way, also because we were already familiar with the Yaskawa Motoman robots. And with the Yaskawa robots I had never had any break-downs or negative experiences. In addition, the contact is good. If there are any questions, I can always call and I am helped right away. The help desk is good."

Local support

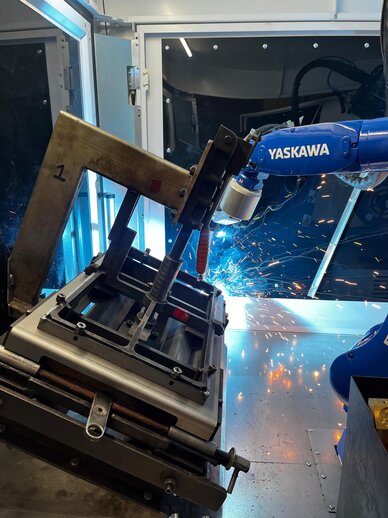

Production has been in Poland since 2005 and the oldest robots there have been there since 2010. "The support from Yaskawa in Poland is also excellent. It is very convenient, that there is someone there who has the parts or the necessary knowledge." In the new welding cell, different parts of the stoves' doors are welded. The hinge with which the door is hung in the stove, the latch and the groove where the glass will be inserted are all made of steel and are welded together in the ArcWorld cell. The eight parts are placed in a mold manufactured in-house and then welded.

The robot welding cell has already become a standard part of the production process; all the different doors have been programmed. "The guy who programmed the welding cell first came into contact with one of your robots on the course at Yaskawa and he has now programmed that thing all the way through, so it's going extremely well. Even the first door that was welded has gone into production. It was not rejected either, which is very special," says De Jong. The robot operators at Janco de Jong also do conventional sheet metal work such as cutting, sawing and drilling in the workshop.

New rules

The rules regarding wood stoves and particulate matter emissions could be seen as an obstacle, however, De Jong does not experience it that way. "You have to turn new rules around so that they work in your favor. The rules apply to everyone, every manufacturer, so if you make sure that you comply with those rules in time and sufficiently, then you are a step ahead of the competition. If word gets out and it turns out that your wood stove is very clean, burns well, then people are actually inclined to trade in their old wood stove."

Cleaner combustion technology

People who are now looking for a wood stove look very consciously at particulate emissions, efficiency and lifespan. The spearhead of product development at Janco de Jong is to make JAcobus stoves cleaner and more efficient. De Jong continues, "You have to try to improve the combustion technique: higher temperature, adjust the oxygen supply, create vortices. The combustion triangle in itself is not very complicated but to get it as good as possible, that is always a quest and does provide a bit of a challenge." As production numbers rise as more people choose Janco de Jong's combustion technology, the various robots in the workshop will allow demand to be met with ease.